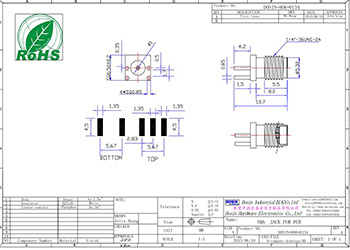

BNC Разъем Прямой Джек Женский Штырь Панель Монтаж Насыпь — RHT-610-0026

BNC RF Connectors are used in surveillance projects for the output of camera equipment when the wire and the camera connection head. It is composed of five independent signal connectors for RGB three primary colors signal and line synchronization and field synchronization. BNC RF Connectors can isolate the video input signal, so that the signal interference between each other is reduced and the signal bandwidth , so that the best signal response can be achieved. Because coaxial cable is a shielded cable with the advantages of long transmission distance and signal stability, BNC RF Connectors are now also used in a large number of communication systems.

Compact Design for less installation space required

Bayonet coupling mechanism provides positive, quick mating and un-mating

50 and 75 ohm irpedance desighs allowcustomers to matchimpedance to system requirements

Desians available for many common BNC coaxial cable types

Complete Variety

BNC Cable Connector

Crimp Type

Solder Type

Compression Type

Twist-on Type

BNC PCB/Panel Connector

Through Hole

Edge Mount

SMT Type

Bulkhead Type

Product Application

Instrumentation

Computer/LAN

Satellite Communications

Automotive/ Aerospace

Broadcasting

Cable Modems

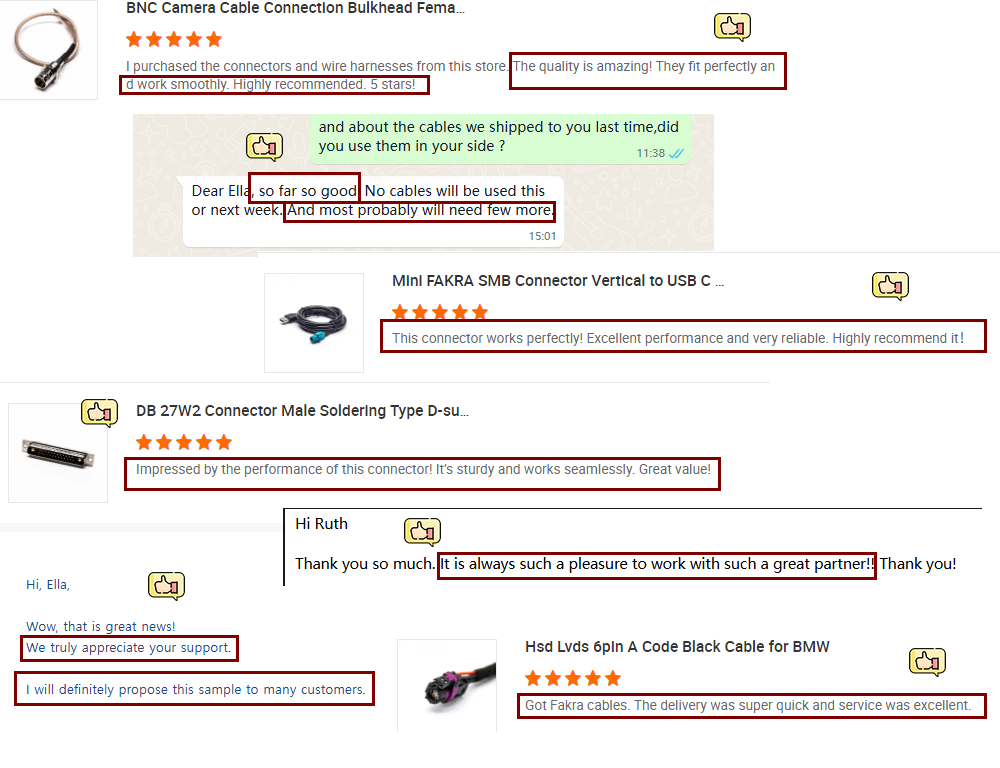

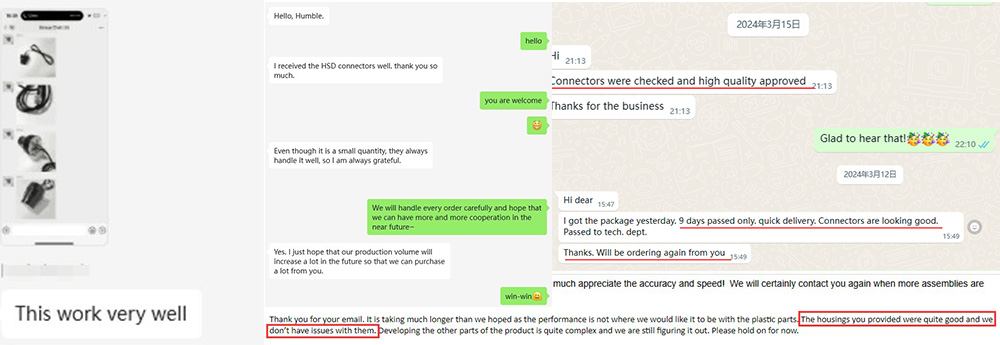

Our Advantages

Physical factory

Having a professional production team, selfproduced and self sold

Quality assurance

Through strict qualitycontrol, ensure quality

After sales system

Actively follow up andpromptly address anyissues

After sales system

Actively follow up andpromptly address anyissues

Production Process

1. Put forward demand

2. Sketch design

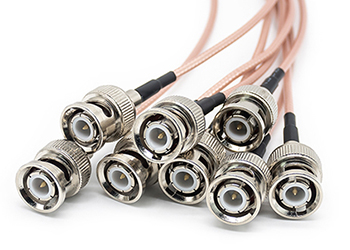

3. Production equipment

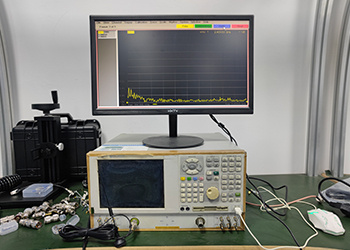

4. Production measurement

5. Product assembly

6. Quality test

7. Product packaging

8. Product packag box

9. Deliver goods

Product Specification

| RF Series | BNC Type |

||

|---|---|---|---|

| Connector Type | Jack |

||

| Contact Type | Female Pin |

||

| Orientation | Straight |

||

| Fastening Type | Bayonet |

||

| Number of Ports | 1 |

||

| Продукция не найдена | 50 ohm |

||

| Mounting Type | Panel Mount |

||

| Mounting Feature | Bulkhead |

||

| Insulator Material | Teflon White |

||

| Shell Material | Copper Alloy |

||

| Shell Finish | Nickel Plated |

||

| Contact Material | Copper Alloy |

||

| Contact Finish | Gold Plated |

||

| Продукция не найдена | 0~4 GHz for 50 ohm |

||

| VSWR | R/A type ≦ 1.30/3GHz, Straight type ≦ 1.22/3GHz |

||

| Dielectric Withstanding Voltage | 1500 V rms |

||

| Working Voltage | 500 V rms |

||

| Center Contact Resistance | ≦ 1.5 MΩ (Milliohms Max.) |

||

| Outer Contact Resistance | ≦ 2.0 MΩ (Milliohms Max.) |

||

| Insultation Resistance | ≥5 × 10³MΩ (Milliohms min.) |

||

| Mating Durability | ≥ 500 Cycles |

||

| Environmental Characteristics | POM -40℃~+60℃, Teflon -55℃~+155℃ |

||

| RF Series | BNC Type |

Connector Type | Jack |

| Contact Type | Female Pin |

Orientation | Straight |

| Fastening Type | Bayonet |

Number of Ports | 1 |

| Продукция не найдена | 50 ohm |

Mounting Type | Panel Mount |

| Mounting Feature | Bulkhead |

Insulator Material | Teflon White |

| Shell Material | Copper Alloy |

Shell Finish | Nickel Plated |

| Contact Material | Copper Alloy |

Contact Finish | Gold Plated |

| Продукция не найдена | 0~4 GHz for 50 ohm |

VSWR | R/A type ≦ 1.30/3GHz, Straight type ≦ 1.22/3GHz |

| Dielectric Withstanding Voltage | 1500 V rms |

Working Voltage | 500 V rms |

| Center Contact Resistance | ≦ 1.5 MΩ (Milliohms Max.) |

Outer Contact Resistance | ≦ 2.0 MΩ (Milliohms Max.) |

| Insultation Resistance | ≥5 × 10³MΩ (Milliohms min.) |

Mating Durability | ≥ 500 Cycles |

| Environmental Characteristics | POM -40℃~+60℃, Teflon -55℃~+155℃ |

| RF Series | BNC Type |

|---|---|

| Connector Type | Jack |

| Contact Type | Female Pin |

| Orientation | Straight |

| Fastening Type | Bayonet |

| Number of Ports | 1 |

| Продукция не найдена | 50 ohm |

| Mounting Type | Panel Mount |

| Mounting Feature | Bulkhead |

| Insulator Material | Teflon White |

| Shell Material | Copper Alloy |

| Shell Finish | Nickel Plated |

| Contact Material | Copper Alloy |

| Contact Finish | Gold Plated |

| Продукция не найдена | 0~4 GHz for 50 ohm |

| VSWR | R/A type ≦ 1.30/3GHz, Straight type ≦ 1.22/3GHz |

| Dielectric Withstanding Voltage | 1500 V rms |

| Working Voltage | 500 V rms |

| Center Contact Resistance | ≦ 1.5 MΩ (Milliohms Max.) |

| Outer Contact Resistance | ≦ 2.0 MΩ (Milliohms Max.) |

| Insultation Resistance | ≥5 × 10³MΩ (Milliohms min.) |

| Mating Durability | ≥ 500 Cycles |

| Environmental Characteristics | POM -40℃~+60℃, Teflon -55℃~+155℃ |

Yes, HD-BNC connectors provide higher clarity and better performance. HD-SDI also includes Mini SDI, which is smaller in size and can save space.

50-ohm BNC connectors are the most common and are suitable for most general applications, typically used in high-frequency ranges.

75-ohm BNC connectors usually provide better performance in lower frequency ranges, such as in television broadcasting and radio frequency spectrum analysis.

Ensure that the connector is fully inserted and locked by rotating it. Make sure the connection point is clean, free from dirt or oxidation, and use high-quality connectors and appropriate tools.

Nickel-plated BNC connectors are widely used in various general environments. They offer good cost-effectiveness, excellent corrosion resistance, and durability, but have higher signal loss in high-frequency applications compared to gold-plated ones.

Gold-plated BNC connectors have superior conductivity and oxidation resistance, but are more expensive.

Brass: Excellent conductivity, corrosion resistance, durability, and ease of machining. Costs slightly higher than zinc alloy.

Zinc Alloy: Lightweight and cost-effective. Conductivity and corrosion resistance are slightly lower than brass.

For harsh environments, brass BNC connectors are recommended.