Corporate Memorabilia

Don’t be afraid of hardships and move forward

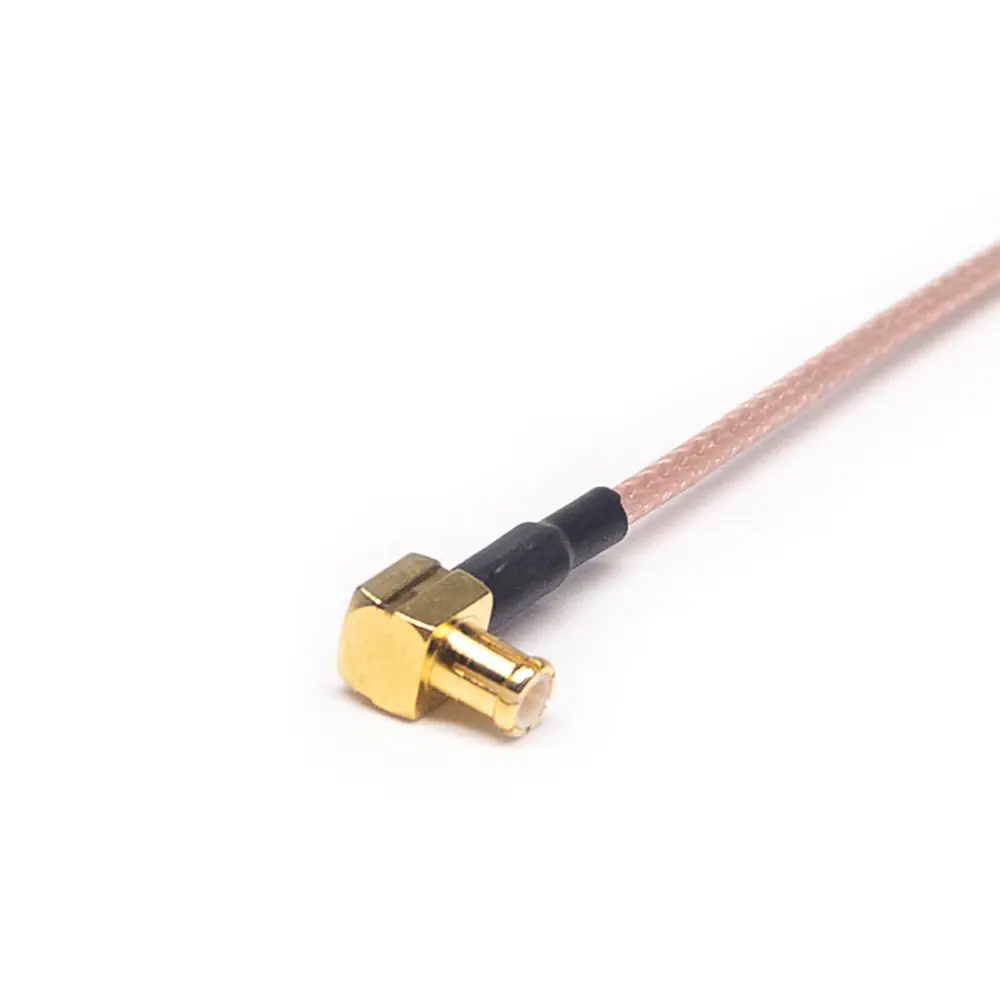

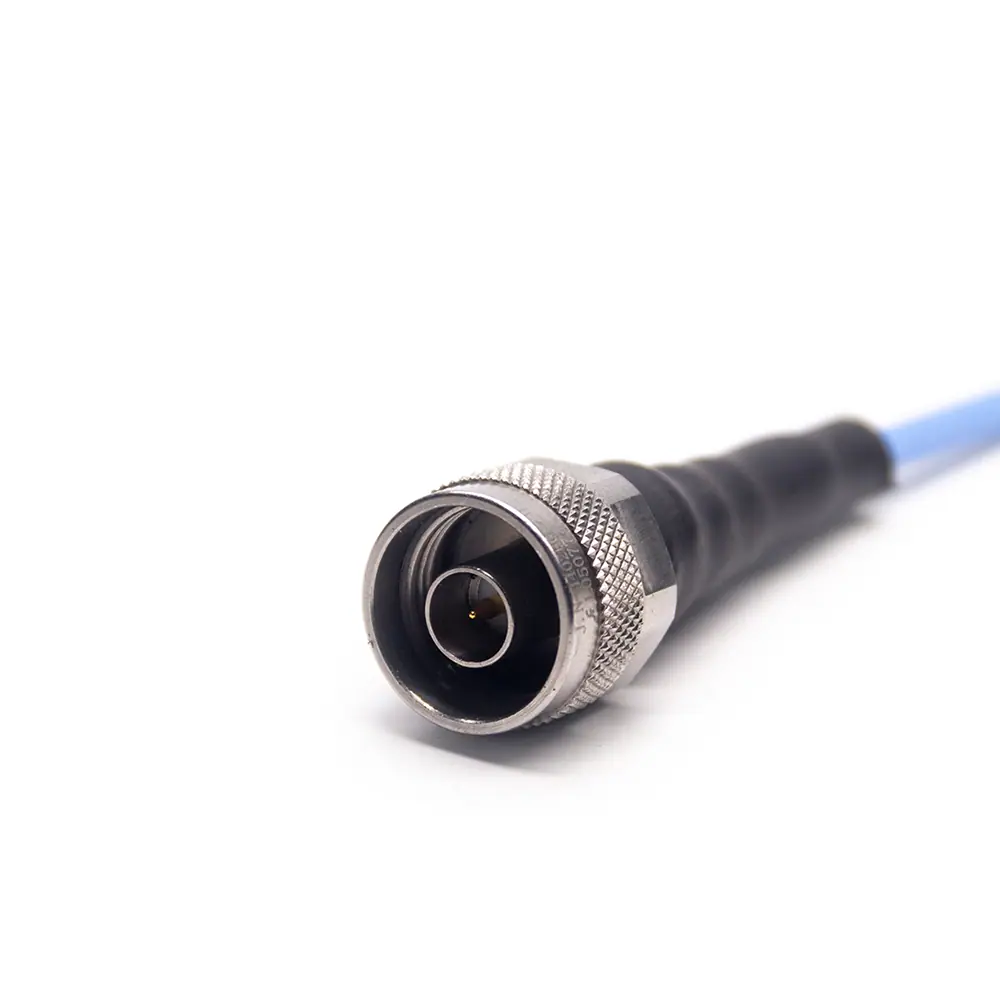

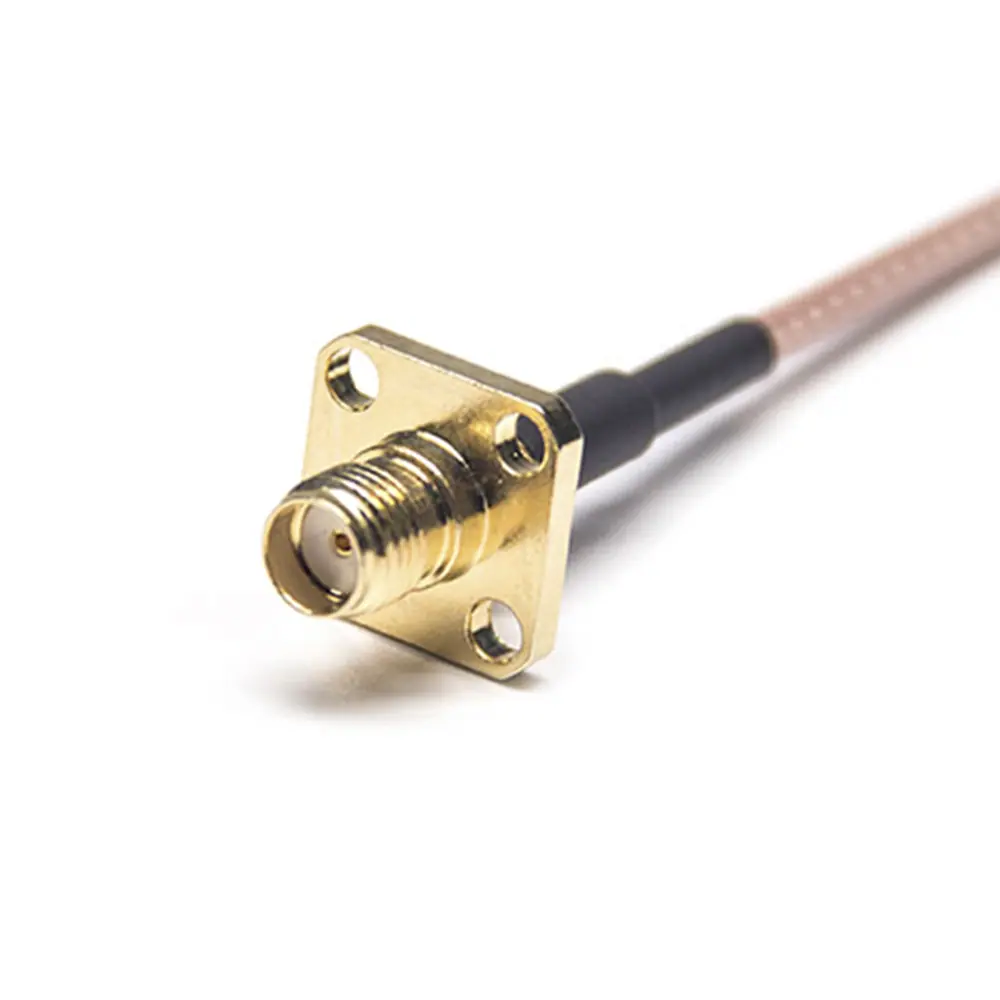

RF Product Production Process

Every process strictly controls product quality

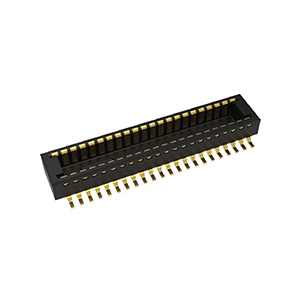

Stamping Workshop

lnsert Metal Plate between the top and bottom mold, and then apply pressure to cuthe plate. ldeal for mass production as high production capacity with only one die mold.

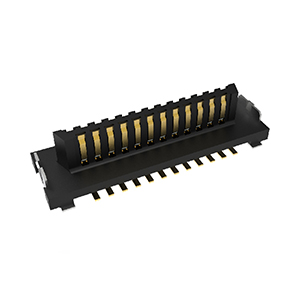

Production Parts

Contact Pin / lron Stand / some small accessories for electical connectors.

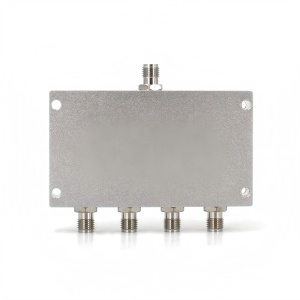

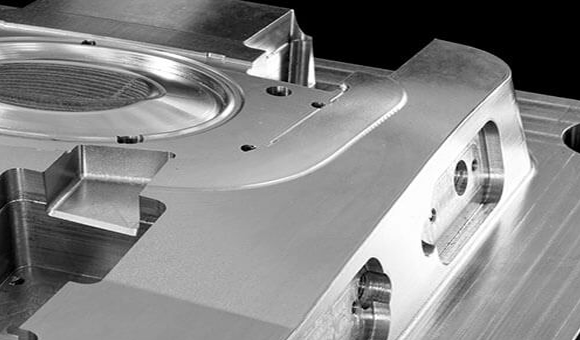

Moulding Workshop

Forcing the molten metal under high pressure into a mold cavity. In Renhotec, this workshop is main for die casting moulding to make Zinc Alloyparts.

Production Parts

Metal body(Zinc Alloy).

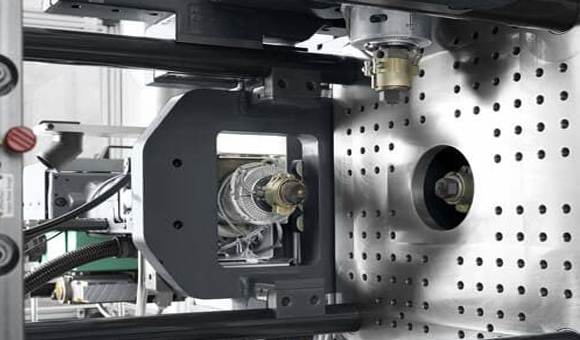

Injection Moulding Workshop

Injection Moulding Workshop lnjection moulding requires to transfer the polymeric material in powder or granule form from a feed hopper to a heated barrel. And then the plastic melted and injected into a mould.

Production Parts

Plastic part, include plastic case, caps and part of insulators for RFconnectors.

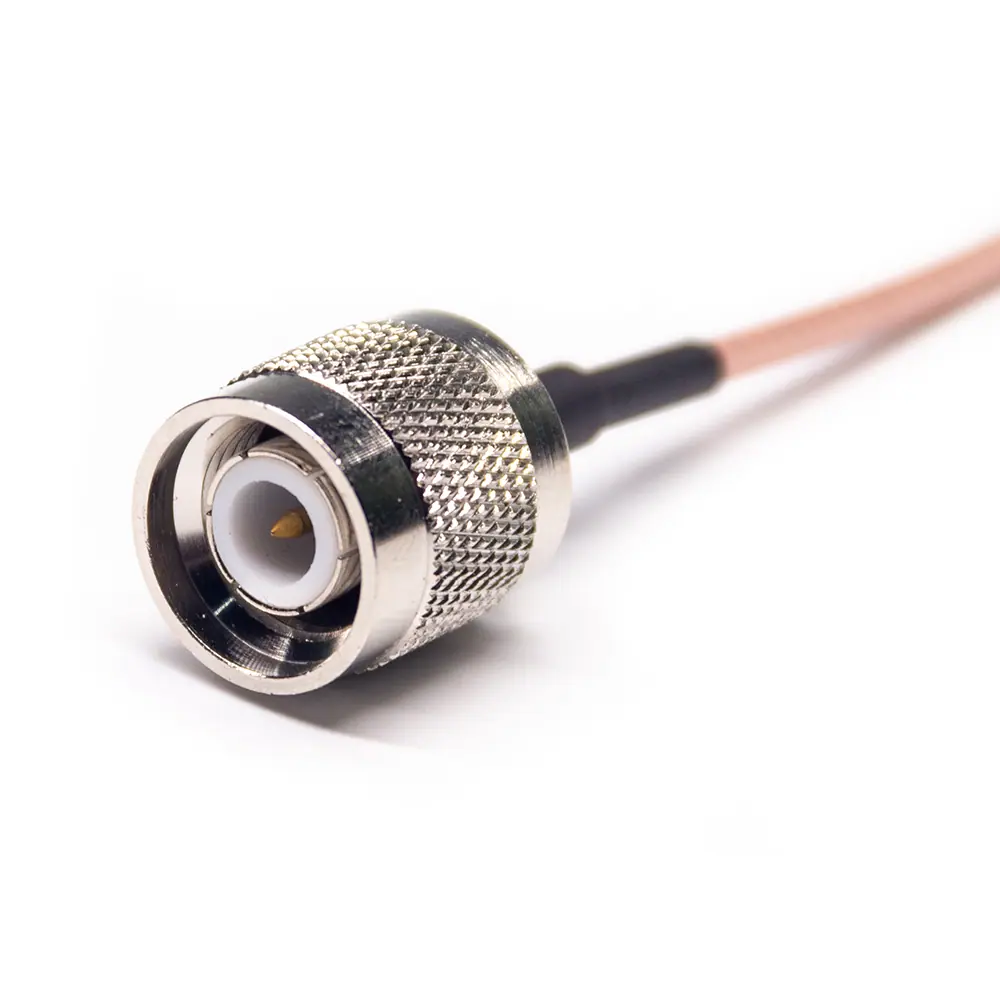

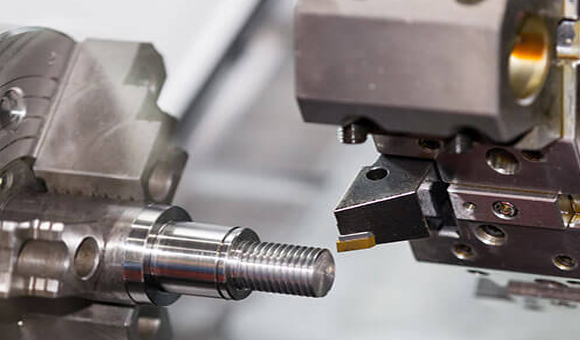

Lathe Turning

Lathe is used to remove unwanted material froma cylindnical workpieces by machine tool. In Renhotec we used lathe to produce copper parts and insulators (Like Teflon).

Production Parts

Matel body and accessories made by copper, Insulators.

Cooperations

The ultimate service to make connection better