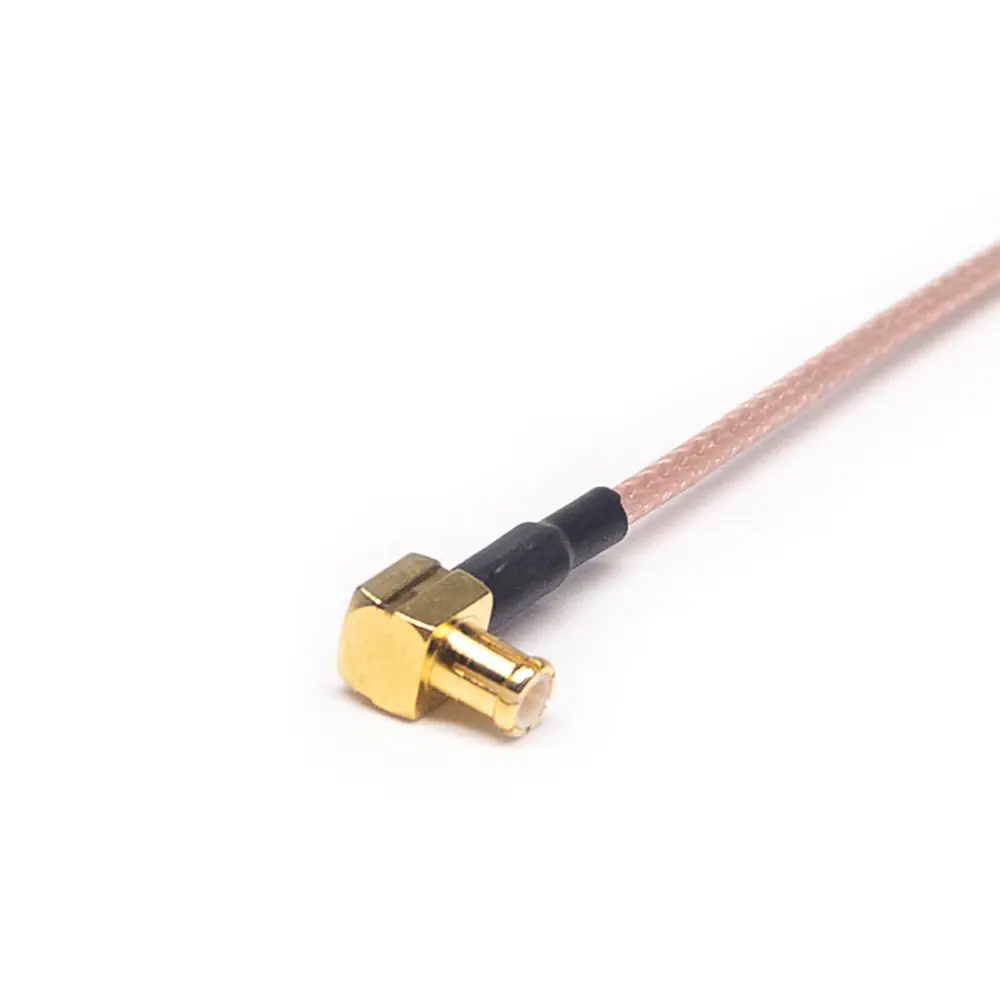

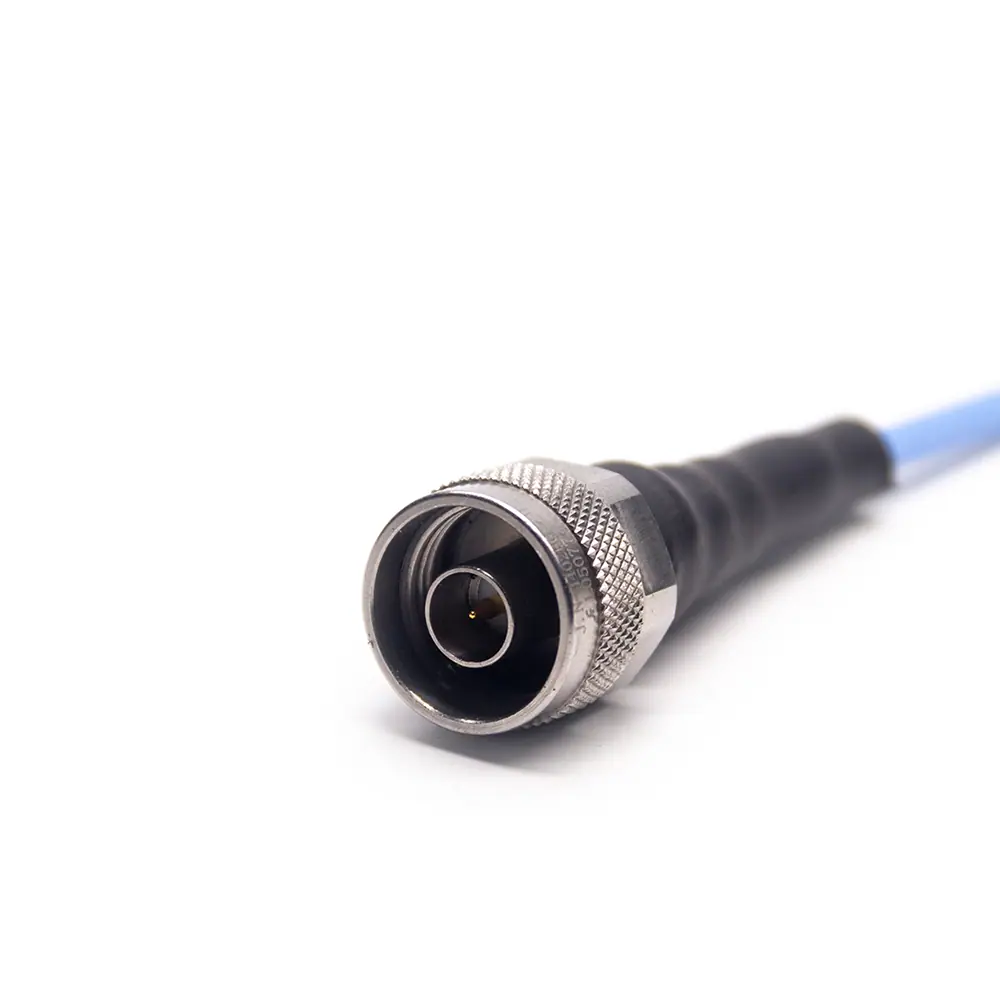

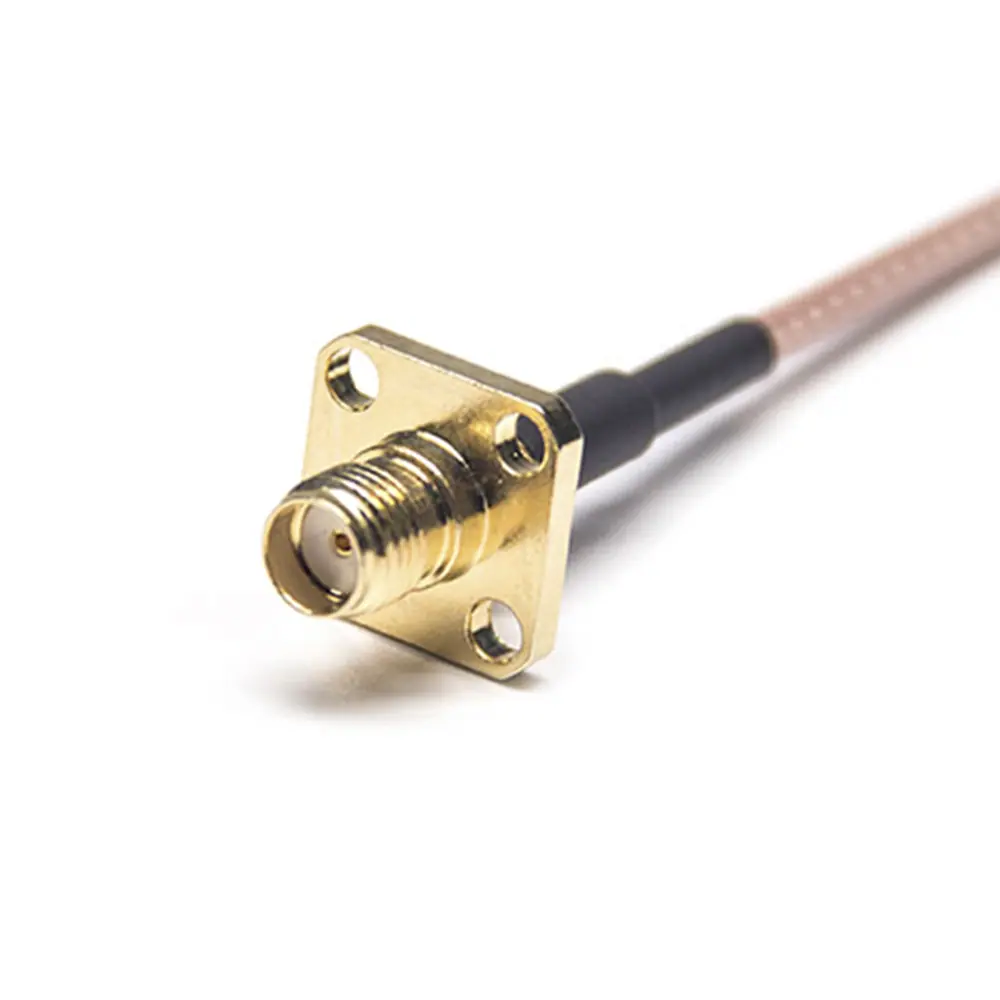

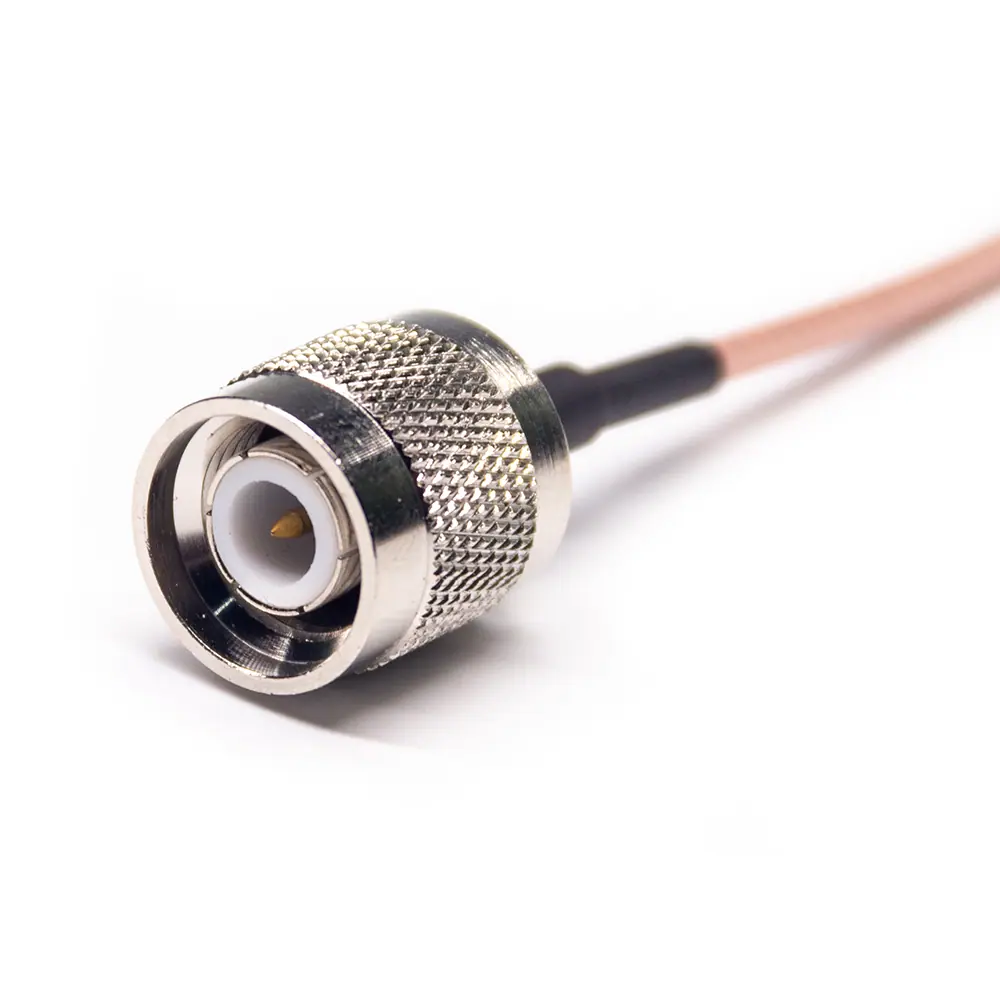

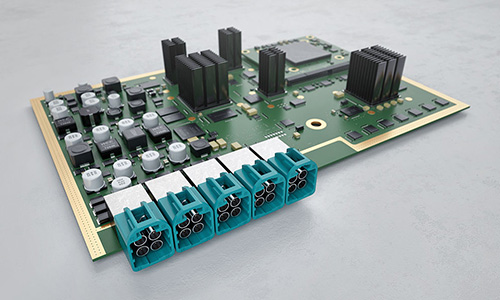

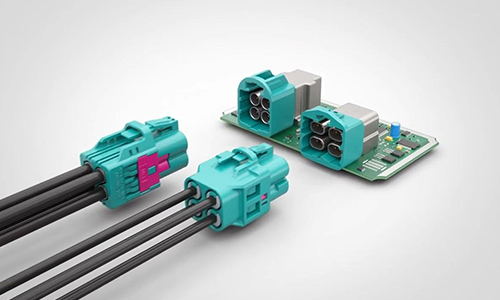

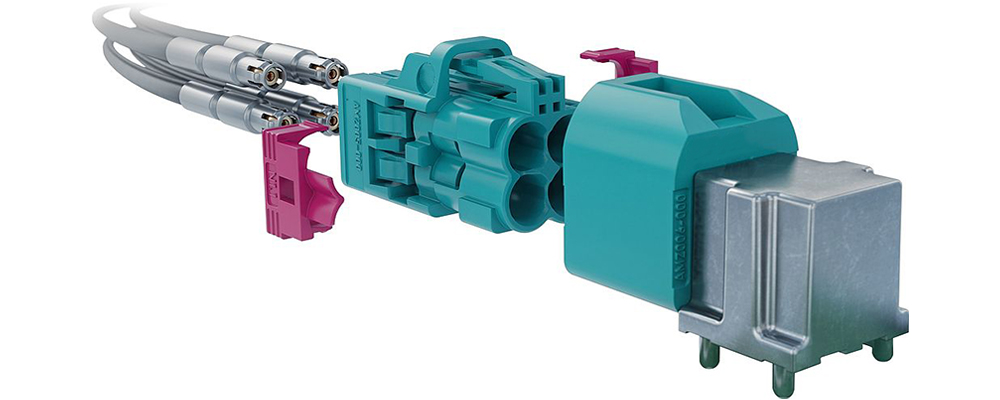

Mini Fakra Connecting Cable Reversing Image Camera New Energy Vehicle Transmission Cable

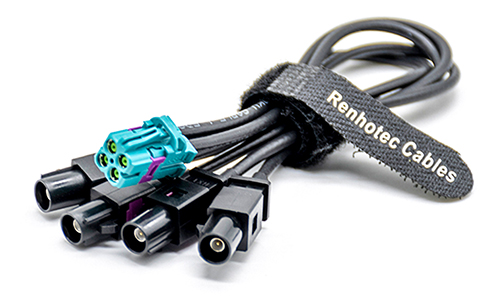

- Mini Fakra connecting cable designed specifically for reversing image cameras in new energy vehicles, ensuring high-quality video transmission.

- Optimized for safety and navigation systems, the cable ensures clear, real-time video output to enhance the driving experience and improve parking safety.

- Durable construction designed to endure the environmental challenges of new energy vehicles, including temperature variations, moisture, and vibration.

- Supports HD video signal transmission with minimal interference, providing reliable performance for reversing cameras and other in-vehicle camera systems.

- Designed for easy integration into new energy vehicle systems, ensuring seamless installation and compatibility with existing camera setups.

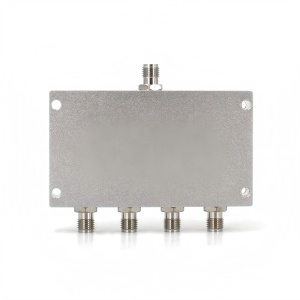

High-Frequency Performance

With frequencies up to 20 GHz, the Mini FAKRA connector can quickly transmit data rates of up to 28 Gbps, making it the highest performing “Mini-Coax” connector system in the automotive industry.

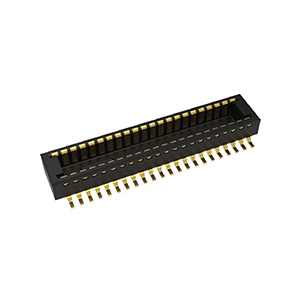

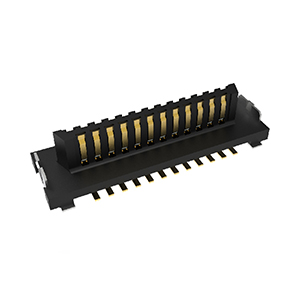

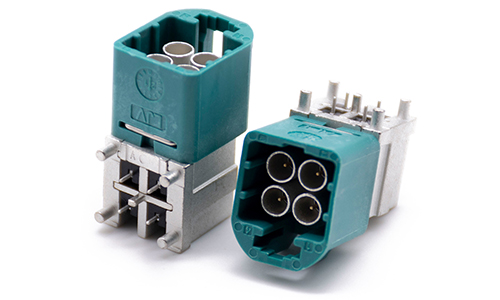

Space-Efficient Design

It takes up to 80% less space than conventional FAKRA connectors, allowing multiple modules to fit into a small frame. Its innovative design meets the need for cost-effectiveness and weight and size reduction.

Cost-Effective Manufacturing

The optimal cost of Mini FAKRA connectors comes from a fully stamped and molded manufacturing process, as well as automated connector mounting and cable assembly, ensuring cost-effective automotive networks, applications and protocols.

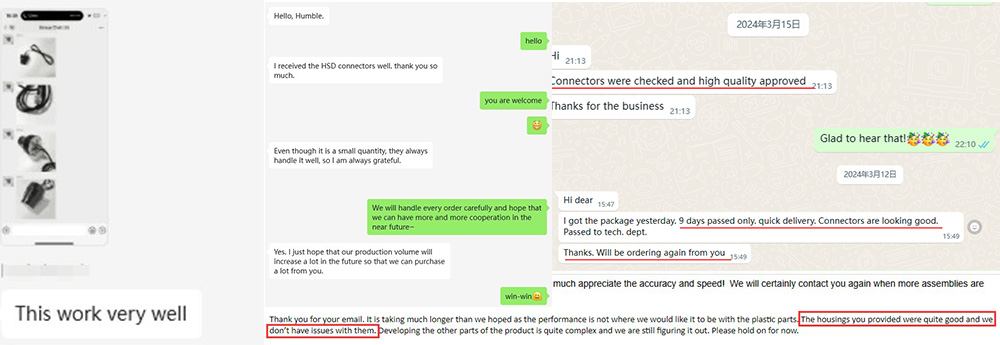

Our Advantages

Physical factory

Having a professional production team, selfproduced and self sold

Quality assurance

Through strict qualitycontrol, ensure quality

Customized

We can customize diff-erent specifications ac-cording to your needs

After sales system

Actively follow up andpromptly address anyissues

Production Process

1. Put forward demand

2. Sketch design

3. Production equipment

4. Production measurement

5. Product assembly

6. Quality test

7. Product packaging

8. Product packag box

9. Deliver goods

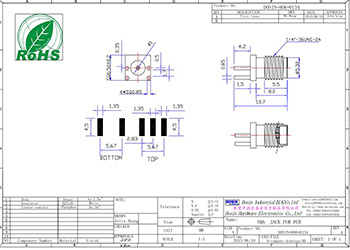

Product Specification

| Impedance | 50 ohm |

||

|---|---|---|---|

| Operating Voltage | 335V max |

||

| VSWR | ≤1.5 |

||

| Operating Temperature | -40°C to +100°C |

||

| Impedance | 50 ohm |

Operating Voltage | 335V max |

| VSWR | ≤1.5 |

Operating Temperature | -40°C to +100°C |

| Impedance | 50 ohm |

|---|---|

| Operating Voltage | 335V max |

| VSWR | ≤1.5 |

| Operating Temperature | -40°C to +100°C |