Uncategorized

Are All Fakra Connectors the Same?

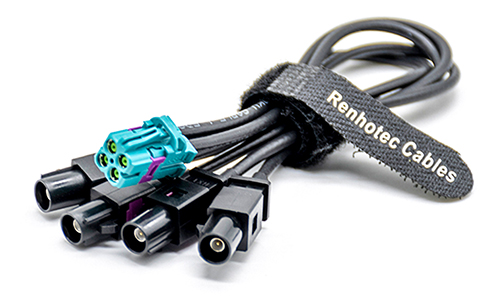

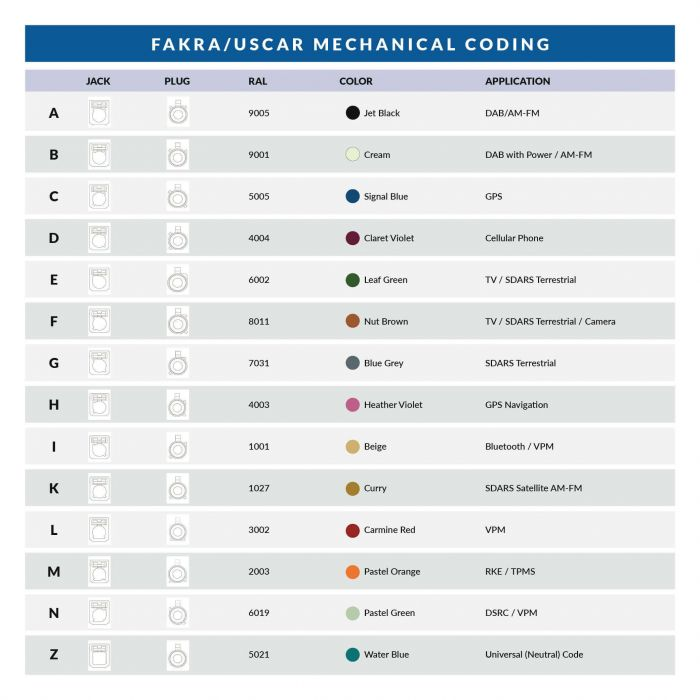

FAKRA connectors are critical components in automotive electronic systems for high-frequency signal transmission, widely used in GPS, in-car entertainment systems, and communication modules. Although all FAKRA connectors adhere to basic standards, different manufacturers offer variations in design, performance, and functionality. This article provides an in-depth analysis of FAKRA connectors from the perspectives of technical principles, design features, performance analysis, and application cases, while comparing the product characteristics of four leading manufacturers.

Technical Principles

FAKRA connectors are based on coaxial cable design, ensuring the integrity and low loss of high-frequency signal transmission. Their core working principles include:

- Signal Transmission Mechanism: Coaxial structure provides signal shielding, reducing electromagnetic interference.

- Physical Structure: Standardized interface design ensures interchangeability and reliability

- Impedance Matching: FAKRA connectors are typically designed with 50-ohm impedance to ensure efficient signal transmission.

Design Features

The design elements of FAKRA connectors include:

- Material Selection: Use of high-temperature and corrosion-resistant materials to withstand harsh automotive environments.

- Mechanical Structure: Precise tolerance control and impedance matching ensure stable signal transmission.

- Standardized Parameters: Compliance with international standards such as ISO 20860 ensures compatibility and consistency.

Specification Comparison

The following is a comparison of FAKRA connector specifications from four leading manufacturers:

| Brand | Dimensions (mm) | Electrical Performance (Bandwidth) | Operating Temperature (°C) | Compliance Standards |

| Rosenberger | 12×8 | 1.5 GHz | -40 to +105 | ISO 20000-6 |

| TE | 10×6 | 2 GHz | -40 to +85 | ISO 20000-6 |

| Amphenol | 11×7 | 2 GHz | -55 to +125 | ISO 20860 |

| Molex | 13×9 | 6 GHz | -40 to +105 | ISO 20860 |

Performance Comparison

The following is a comparison of FAKRA connector performance from four leading manufacturers:

| Brand | Signal Transmission Efficiency | Durability (Insertion Cycles) | Environmental Adaptability (Temperature Range) |

| Rosenberger | High | 500 cycles | -40°C to +105°C |

| TE | High | 500 cycles | -40°C to +85°C |

| Amphenol | High | 600 cycles | -55°C to +125°C |

| Molex | Very High | 700 cycles | -40°C to +105°C |

Application Scenario Comparison

The following is a comparison of FAKRA connector application scenarios from four leading manufacturers:

| Brand | Application Scenarios | Specific Cases |

| Rosenberger | Complex Coding Systems | High-end in-car entertainment systems |

| TE | Mass Production | GPS modules in mainstream vehicle models |

| Amphenol | Extreme Temperature Environments | Communication modules in heavy-duty trucks |

| Molex | Advanced Driver Assistance Systems (ADAS) | Sensor connections in autonomous driving systems |

Selection Recommendations

Based on the comparison results, the following selection recommendations are provided:

- Cost-Effectiveness: Choose TE Connectivity products, suitable for mass production and cost-sensitive applications.

- Extreme Environmental Adaptability: Choose Amphenol products, suitable for applications in extreme temperature environments.

- High-End Applications: Choose Molex products, suitable for advanced driver assistance systems (ADAS) and autonomous driving applications.

- Complex Coding Requirements: Choose Rosenberger products, suitable for applications requiring high reliability and complex coding systems.

FAKRA connectors play a vital role in automotive electronic systems due to their high bandwidth, anti-interference capabilities, and environmental adaptability. Products from different manufacturers offer unique advantages in performance, design, and cost, and the choice should be based on specific application requirements. As smart vehicles and autonomous driving technologies advance, FAKRA connectors will continue to play a key role.

Reference:Technical Specifications of FAKRA Connectors